M.E.T.T.S. - Consulting Engineers > Opinion Pieces & Conference Presentations > Making Nitrogen a Valuable Co-product of Helium Recovery from Natural Gas

Making Nitrogen a Valuable Co-product of Helium Recovery from Natural Gas

Dr Mike Clarke, MPESA, CPEng, FIEAust, FAusIMM, RPEQ

This paper was originally published in "PESA News" (Petroleum Exploration Society of Australia), Issue No. 158, Third Quarter 2020.The adage "the customer is always right" applies to the helium production and distribution industry. Customers may be looking for a gaseous industrial grade, say 70% He, an A-Grade gaseous product (say 99⋅99% He) or a very pure liquid product with a purity of >99⋅995% He. To produce the two higher grades cryogenics will be required. When cryogenically producing liquid helium (LHe) or very pure gaseous helium, liquid nitrogen (LN2) and/or gaseous N2 will be a co-product. Nitrogen can be a useful and valuable co-product that can assist petroleum exploration and production. The Co-production of helium and nitrogen can be win-win activity; this is the theme of this article.

Nitrogen comprises around 78% of the earth's atmosphere as compared to Helium at around 5⋅2ppm; nitrogen is an industrial gas with its major production costs being, electricity supply (usually shared with oxygen and argon production), feed air clean-up (also shared with oxygen and argon), and compressed and liquefied gas handling and logistics. It is an important gas that is used in the production of nitrogen containing chemicals (e.g. urea, ammonia, nitric acid...), as a non-reactive atmosphere in drug packaging, food storage and electronics production and steel production and tempering.

Nitrogen is normally produced in large cryogenic Air Separation Units (ASUs), where the respective boiling points of Oxygen (-183°C), Argon (-185⋅8°C) and Nitrogen (-195⋅8°C) are used to provide three marketable gas streams. Nitrogen can also be separated from Natural Gas, including natural gas that also contains Helium (boiling point -268⋅9°C, which is 4⋅22K above absolute zero). It also has a place in cryogenics where its low boiling point is used to facilitate the sale and distribution of "cold" as Liquid Nitrogen (LN2).

Nitrogen is also present in many natural gas occurrences. Helium in recoverable concentrations occurs less frequently than nitrogen, so the following rule can be applied: If nitrogen is present in a gasfield then helium MAY be present; if helium is present in a gasfield nitrogen WILL be present and in a higher concentration than the helium. Note 1: Many gas well operators are checking through old analyses where helium was not analysed for to see if nitrogen was present. In a well or gasfield workover helium will now be on the petroleum geologist's check-list for analysis. Note 2. The relationship between the presence of helium with nitrogen is not fully understood; it may be a result of co-migration of small diameter gas molecules (nitrogen)/atoms (helium) through semi-porous strata.

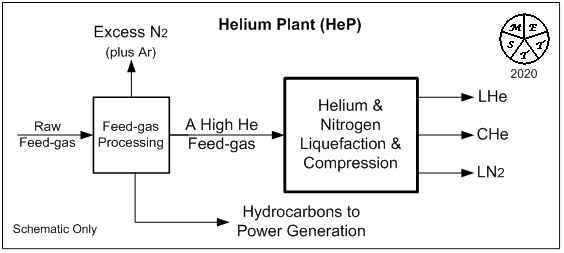

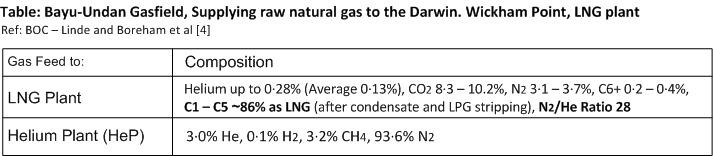

An example of helium concentrations in the gas feeds to a LNG plant and a HeP

The Raw Feed-gas could be the off-gas of a LNG train or a high helium (3 to >10% He), low hydrocarbon natural gas. The hydrocarbon content could be a few percent, being the residual H-C from LNG production or say a H-C content ranging from 10 to 30% of a raw low H-C natural gas. The HeP feed-gas could be 15% He, 85% N2 gas mix or an industrial-grade He of say 70% He and 30% N2. The HeP products will be Liquid Helium (LHe), Compressed Helium (Che) and nitrogen, probably as Liquid Nitrogen (LN2) and compressed nitrogen gas. The Feed-gas Processing Plant (See Figure 1) and the HeP would use adsorption and cryogenic technologies to achieve separations. Note 3. Helium separation process produces a clean liquid nitrogen that is ready for sale as liquid or gas and transport to customers. Note 4. The N2/He ratios of raw well gas vary widely. The Bayu-Undan gas has a moderate ratio (28:1) that would still produce a surplus of LN2 over that needed for LHe product transport and plant heat exchange.

Nitrogen as a Co-product of Helium Production

One reason why nitrogen is used as a drilling gas in preference to air is the absence of oxygen. Its inability to support combustion makes it a useful gas around petroleum (gas and liquids) exploration. It is used use in drilling, injection for reservoir and wellbore pressure maintenance, and in coiled tubing operations. It prevents downhole fires and allows a lighter drilling fluid to be used [1]. Nitrogen Injection (NI) is also useful in Enhanced Oil Recovery (EOR) in deep reservoirs where it is used to increase oil swelling and viscosity reduction and limit crude oil vaporisation [2 and 3]. NI increases oil recovery.

The production and transport of nitrogen on a developed (or developing) gasfield

The technology used in remote helium separation can incorporate a number of synergies. The power generated on-site will be used for running the gas separation units, pumping and compressing gas and services (including the boss's beer fridge). Energy would be available for both helium and nitrogen production and logistics.

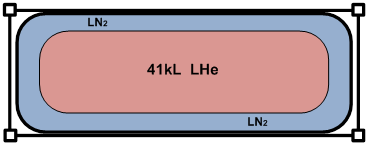

Liquid nitrogen is required as a heat transfer working fluid in a LHe plant but also needed as a thermal buffer in LHe storage and transport. In Figure 2, a schematic of a helium transport and storage flask that uses LN2 as a sacrificial gas; LN2 boil-off and venting is used to prevent LHe boil-off. Note 5. Generally LHe can be stored and transported without loss for up to 45 days; re-liquefaction is required if longer holding periods occur.

Note 6. These tanks are suitable for road and seaborne transport but not rail due to high shunting forces.

Looking beyond the HeP fence

Remembering that liquid and compressed nitrogen are industrial commodities of relative low value, supplying them into remote gasfields from distant industrial complexes will be a relatively high logistics cost, low commodity cost exercise. LN2 and CN2 if produced in a helium bearing gasfield could be available to extensive regional gas provinces. Note 7. If commercial helium finds are confirmed in the Amadeus Basin, nitrogen could be supplied onto the Amadeus Basin (e.g. the Palm Valley, Dingo and Mereenie), the WISO, the Northern Cooper, Beetaloo and perhaps the S W Georgina and Nicholson basins.

Helium is also present in the N W Shelf petroleum fields [4]. Nitrogen could also be a co-product of existing (e.g. Bayu-Undan) or future gas developments that have helium recovery, like Greater Sunrise. The use of nitrogen as a drilling aid is applicable especially if the petroleum reservoirs are at depth, as is the case in parts of the N W Shelf.

Looking beyond the petroleum industry as a potential customer, "cold" in the form of LN2 could be provided to the food industry, with focus on the meat processing. It will take entrepreneurial spirit to put together scenarios for utilising a bulk pure nitrogen resources in remote Australia when LN2 becomes available.

Helium into the future, COVID-19 and all

From 2015 to the present there have been doomsayers reporting on helium shortages. With the exception of a brief interruption in supply in 2017 caused by a political argument between Qatar and Saudi Arabia where the Saudis blocked the Qatari helium logistics, the flow of helium from producers to users has been steady. Increases in the price of A Grade Helium (>99⋅995% He), being either gas or liquid, have occurred but this has been caused by a tight trading situation between the small number of primary helium traders/ suppliers. New resources (e.g. Tanzania, South Africa and Siberia) are pending development, whilst Australia may co-operate with Timor Leste regarding the development of the Greater Sunrise gasfield and its contained helium.

COVID-19 may be reducing the medical use (being MRI scans) and the industrial use (as a flooding gas in electronics manufacture) and causing hitches in logistics (still to become apparent), however this reduction in use will only be marginal. Logistics failures that result in helium blow-off and cryogenic tank heating could be a major supply hazard that effects gas wholesalers and distributors.

On Tuesday 2nd July, 2020, Prime Minister Scott alluded to the development of conflict situations post COVID and subsequently announced a very substantial increase in Australia's defence spending. If conflict occurs helium would be a strategic mineral that Australia and its allies must have. The uses will include strategic rocketry, heat sensing and tracking and aircraft tire inflation (as was used by the US in WWII).

Features of a successful natural gas find with helium/nitrogen as significant components

- Helium is worth 20+ times the value of natural gas (comprising methane and C2 - C5 gases); nitrogen as an inert gas has little value except if it is required to complement a cryogenic separation system and facilitate the export of LHe,

- Nitrogen produced during the NG separation processes contains no oxygen and little or no CO2,

- Liquid nitrogen that is surplus to LHe export logistics needs is produced at little direct cost and is currently wasted to the atmosphere, and

- Liquid nitrogen is a convenient source of "cold" that can be exported by road, rail or sea; as such it has value where there is an existing market or a market that develops once nitrogen becomes available.

- Always be aware of the possibility of having helium and nitrogen in natural gas, and always include helium (plus nitrogen and hydrogen) in the suite of analyses undertaken of samples,

- Have both high-pressure (as steel gas-bombs) and low-pressure (as impervious bags - e.g. the TEDLAR system) samples taken both inside and outside the expected gas zones in the wells, and

- Have qualified and experienced people collecting gas samples and organising/supervising the sample analysis logistics,

- Dispatch samples to recognised and approved analytical laboratories as soon as possible after collection (helium can permeate through plastic and steel over time), and

- Use a methodical and secure reporting system.

Conclusion

Helium should be analysed for when natural gas is being analysed. If helium is present in natural gas finds it should be considered for separation, processing and monetisation. Liquid helium logistics can be difficult because of boil-off but good management can largely get over those challenges, provided that conflict politics do not get in the way, as happened with Qatar in 2017. Helium is not a rare element/mineral, however its recovery, storage and transport are costly. Supply and demand can expect to be relatively balanced with shortages in supply being made up by the opening-up of known resources (and suspected resources) where presently uneconomic helium will become economic.

Nitrogen from natural gas containing economic helium has an advantage over atmospheric nitrogen in that its cryogenic costs are largely met by the helium separation. Nitrogen as gas or could be used by the up-stream petroleum industry and regional industries that need "cold".

If supply ever gets very tight, there is always the around 5⋅2ppm of atmospheric helium that can be tapped. Where very large air separation plants exist (probably as part of a steel complex), the economic extraction of helium with neon, krypton and xenon becomes possible, as demonstrated in the Ukraine [5]. The cost of atmosphere derived helium is presently around two to three times that of natural gas derived helium, however more large air separation plants (perhaps in China) would likely see that price drop as new supply from air separation enters the market. If nitrogen, oxygen and argon (comprising 99⋅96% of air after the removal of carbon dioxide and water vapour) can be recovered from air profitably and produce a by-product of gas containing the essentially the noble gases, He, Ne, Kr and Xe, then air sourced helium is a competitor with natural gas sourced helium; but will this ever happen?

The answer to the above possibility of air sources becoming a major helium resource is up to future helium need, demand (the willingness to pay) and future security effecting the supply balance. The probable answer is no if major new finds of helium bearing natural gas become common place and there is peace and security in those new production regions.

Note of thanks

Geol John Heugh, Consulting Petroleum Geologist and former MD of Central Petroleum Ltd., is thanked for his comments on the value of nitrogen in petroleum exploration and production well applications. John emphasised that its use provides another positive step in safety management during drilling, an increase in drilling efficiency from having lighter drilling muds, and as a driving gas during Enhanced Oil Recovery.

Sources

1. Nitrogen use increasing downhole, in reservoir work. Off-shore Magazine, August 1, 2000, www.offshore-mag.com

2. Nitrogen Injection, Enhanced Oil Recovery (EOR), Schlumberger Oilfield Glossary, www.glossary.oilfield.sib.com

3. Enhanced Oil Recovery, EOR Techniques and Nitrogen Injection, Duraya Al-Anazi, Cseg Recorder, Vol 32, No 8, October 2007

4. Helium in the Australian liquefied natural gas economy, Chris Boreham et al, APPEA Journal 58(1) 209-237, May 2018

5. Neon Gas Skyrockets: Ukraine or China? Jeff Dorsch, September 18, 2015 http://electronics360.globalspec.com/article/5742/neon-gas-skyrockets-ukraine-or-china

NOTE:

You are welcome to quote up to a maximum of three paragraphs from the above conference presentation, on condition that you include attribution to this website, as follows:

SOURCE: M.E.T.T.S. Pty. Ltd. Website http://www.metts.com.au

M.E.T.T.S. Pty. Ltd. - Consulting Engineers PO Box 843, Helensvale QLD 4212, Australia TEL: (07) 5502 8093 • (Int'l) +61-7-5502 8093 EMAIL: metts[at]metts.com.au Copyright • Privacy • Terms of Use © 1999-2020 M.E.T.T.S. Pty. Ltd. All Rights Reserved. |

.