M.E.T.T.S. - Consulting Engineers > White Papers > Battery Backups for Nuclear Power Plants

Battery Backups for Nuclear Power Plants

Can New Power Battery Technologies Create a Higher Level of Backup Security?

Dr. Michael C. Clarke

CPEng, FIEAust, APEC Engineer, IntPE (Aus), FAusIMM, RPEQ (Mining & Chemical)

M.E.T.T.S. P/L, Consulting Engineer, Infrastructure Developing & Resource Management

Email: metts[at]metts.com.au

Preamble/Abstract

The Fukushima Nuclear Disaster of March 2011 [1] is an example of how seemingly extensive and presumed adequate defences can be overwhelmed by an event of such magnitude that engineering planners did not imagine such a calamity. The Fukushima is an example of where the planners "got it half right", the reactor control rods did shut-down the operating reactors when the earthquake occurred, however they got it half very wrong when it came to providing the required power backup to maintain reactor system cooling and used fuel-rod cooling during and post the tsunami inundation.

In the eight years since the Fukushima disaster concepts for making emergency backup power supply to nuclear reactors situated on seashore sites more resistant to tsunami threats have been created. Those efforts have very much been centred on placing backup generation sets away from the seashore to where the tsunami threat is low; the use of more remote sites and elevated sites have been suggested for diesel power generation-sets. The placement of nuclear power stations away from coastal sites has also been considered, however the efficiency of nuclear power generation systems using seawater cooling for maintaining high conversion (nuclear energy to electrical energy) efficiencies with fuel burn-up is a major advantage if it opportunities for such locations exist.

This paper discusses the potential for new battery technologies to be the backup power supply or a supplementary power source to existing backup systems that are presently usually supplied by emergency diesel generators (EDGs) that are the Nuclear Industry's norm. Although heavy duty batteries, being lead-acid, have been a feature of electricity supply system for around a century and a half, the newer battery technologies have still to prove themselves as storages for very large amounts of energy required to power cities, transport and industry; If the new batteries can deliver power to our electricity dependant society, their use as backup for nuclear energy plants should be seriously considered.

Introduction

Backup electricity supply systems for nuclear power plants are a necessity; the backup systems are designed to provide cooling for spent fuel elements, cooling of residual heat produced in shut-down reactors (being decay heat) and for maintaining services (e.g. system control, lighting, communication, and ventilation to the reactor, the power generator block and ancillary plant. The electricity demand required by backup systems will vary with reactor size, efficiency, design (including fuel selection and the design of fuel element housing), the quantity and cycle of spent fuel and the nuclear waste management system.

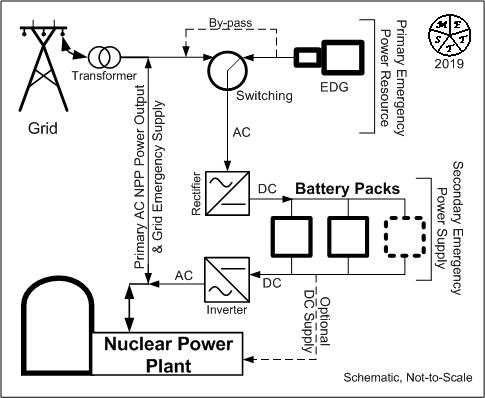

The capacity and endurance (the total stored energy and the time period that the backup system can deliver the required energy demand) of backup systems should be able to the calculated by accurate modelling of the electrical, mechanical and service uses of energy. The major question will be, "how long will backup energy supply be required in the worst event scenario?" The answer will require risk/hazard analyses coupled with knowledge gained post Fukushima and a little conservative stargazing. A second concern for battery electricity storage is that the electricity going into storage units will be alternating current (AC) whilst that exiting storage will be direct current (DC), so questions will need to be asked as to the performance and reliability of rectifiers, inverters and very high-speed switches.

Back-up and auxiliary power supply can take various forms with operating connection to the power grid being the obvious immediate choice if the connection is operational and there is reliable dispatchable power available. The second back-up is usually Emergency Diesel Generators (EDGs) that fire diesel or other suitable fuels such as LFO. The EDG system usually has redundancies including multiple sets and twinned sets, sometimes separated by distance. Batteries are used for cold-starts for EDG sets and the powering of control, security and communication systems. Compressed air can also be used for providing energy for EDG cold-starts and gas turbine sets can replace reciprocating diesel engine sets in some instances.

For over a century lead-acid (LABs) were the primary rechargeable industrial battery. LABs are still the principal energy storage for operating submerged diesel-electric submarines and were the only realistic battery technology that could be applied to powering electric vehicles; this is now changing. LABs are used for NPP backup for starting EDGs [2] but there may be better options on the way.

New battery systems are now being developed that can have a greater power density (in terms of energy stored per unit of mass and/or volume), are faster to recharge, have greater useable charge and discharge efficiencies (and hence waste less energy as heat), lower self-discharge rates, improved shelf-lives, have an improved constant peak voltage discharge to time relationship, improved cycle durability (how many cycles before noticeable declines in performance occur), very low thermal runaway propensity and low fire and explosion hazard potential. These batteries are likely to be an improvement on existing lead-acid batteries that are presently used in limited capacities in NPPs and have the potential to replace or supplement EDG sets in supplying emergency power shortly, say for some hours, after a SCRAM.

A question of importance: Can new battery technologies be used to increase nuclear safety and avoid disasters such as the Fukushima? [1]

The crucial need is to have reliable power back-up, when needed, available with very short lag-times, in quantities required for all foreseen emergencies and through periods of potential disruption. Batteries have advantages over EDGs that should be investigated and quantified with respect to new and still developing technologies, and if proved to be significantly superior, used in existing and future NPPs. If battery technologies are developed such that EDGs are downgraded to a lesser role in supplying power, emergency power supply security should be enhanced.

Discussion

Battery technology has greatly advanced over the last twenty years after a period of one hundred years of hiatus. The drivers have been the development of laptop computers, mobile phones and other devices and more recently electric vehicles that can compete in range and energy efficiency with petrol/diesel power vehicles (but not yet compete with price). New battery technologies are still developing and it is too early to definitively state what technologies will be the winners and losers with respect specific applications, including heavy duty power standby units for critical infrastructure such as NPPs.

Nuclear power plants are critical infrastructure requiring power backup on a "guaranteed basis". The Fukushima disaster showed that diesel fired standby generators could be overwhelmed by tsunamis and associated occurrences. Power supply units that have rotating mechanical parts take, seconds to start-up and supply power as needed, require external fuel (of guaranteed quality) with combustion air and need active cooling systems are not the appropriate as the primary power backup systems for NPPs.

Lead-acid batteries have been used in the past to supply and backup urban and industrial power supply. From experience, it is noted that Sydney, Australia has/had an extensive DC power supply that was at one time backed-up by large lead-acid batteries. Australia's present submarine fleet is powered through lead-acid batteries, however future diesel-electric submarines will likely be powered through advanced next generation industrial-scale batteries. NPPs should likewise be backed-up by similar batteries.

Batteries for NPPs should be characterised by, secure dispatchable power output, very high charge and discharge cycle performance, security from uncontrolled cascading discharge, zero gas discharge, low internal charge and discharge resistance, passive cooling and no moving parts (e.g. electrolyte circulation) and acceptable energy efficiency, specific energy and energy density and cost. Note: On a multi-billion dollar NPP the cost of a primary hazard reduction system should not be a governing factor in its construction, operation or maintenance.

Robustness of the battery backup system should be priority; following the earthquake and the Fukushima tsunamis the lack of robustness in supporting systems being, access, transmission line integrity and communications became obvious. Relying on business-as-usual access and communications are potentially major risks, especially if access to emergency generation plant (as may be held by electricity wholesalers and emergency agencies such as fire brigades) and communications are knocked out.

Batteries, EDGs and outside sources (inclusive of dedicated diesel gen-sets, regional backup batteries, grid back-up/bypass lines and private major gen-sets) should be noted and included in emergency plans however they should not be the core alternative supplies. Regular safety exercises that can identify new technologies will also assist such that the backup power systems reflect new options for NPP safety. In the future regular hazard management estimations should include the analysis of the power backup systems including how each level of backup comes in (and goes out).

Cooling and Other Power Use Systems for Nuclear Power

The existing backup systems include, limited battery supply, linking back to grid and bringing in on-site diesel generation to provide a full dispatchable and variable supply to meet the demand of the reactor and ancillary services. (An example of the diesel backup for a 600 MWe Pressurised Water Reactor was 10 MWe [in two 5 MWe sets] with diesel fuel for a week in immediate storage [2]). EDGs, being usually reciprocating engine sets can in some circumstances be replaced by gas turbine sets (G/Ts); G/Ts however have longer start-up and full-power times and when required for rapid start-up require volatile fuels.

Fuels for diesel engine sets may include, Avgas, natural gas supplemented with diesel and condensate; natural gas, Avgas and condensate being fuels that should not be used inside a NPP perimeter due to high flammability. G/Ts can have a role in NPP emergency generation if located at "safe" distance outside the NPP perimeter.

New nuclear power stations are likely to still be situated in good proximity to seawater cooling opportunities. Air cooling, freshwater cooling and hybrid cooling (air cooling boosted by an auxiliary water-cooling) are used, however in tropical, sub-tropical and many temperate situations high water flux direct cooling provided by seawater is required for achieving acceptable cooling efficiencies. Post Fukushima new fail-safe cooling systems are required to significantly lower risk and to regain social-license-to-operate (SLTO) for the nuclear energy industry, especially where NPPs rely on seawater cooling. (Suggestions to build Australian power reactors along the coast have been howled-down by opponents who claim the beautiful coast will be spoilt by such plant; in reality some NPPs along the very long coastline would be hardly noticeable.) NPPs that have major isotope production and research facilities also have a major uninterruptable power need; these units plus their administration divisions should be linked in with the NPP's backup power supply.

Nuclear generation systems that burn-down fuel more efficiently, such as Accelerator Driven Reactors (ADRs) should have lower but relatively accelerated heat production in spent fuel elements; the cooling of spent fuel should thus be more efficient (complete), safer and simpler in these advanced systems. ADR's are however still a future technology that needs development to full-size demonstration units, and therefore will require substantial national and international investment to become a reality.

Desirable Battery Characteristics

A battery used for NPP backup must be able to supply its designed emergency power load (in MW or kW) and output (MWh or kWh) in a very short lag-times (say <10s to full required emergency power [3]), without significant deviation in performance over long periods of time and potentially multiple demand events. The batteries must be fully rechargeable no matter what their initial charge level is before recharging, including capability of being at zero charge prior to charging. Another useful characteristic is that the new batteries will likely have very low or preferably zero "dead charge", that being charge that cannot be accessed.

Nuclear facilities, including power plants, come under strict international safety, operational and reporting regulations and rules; these rules include managing the threat of fire or heatings. Some battery types have been shown to have a propensity to chemically cascade and thus heat outside the normal operational heating ranges. Those batteries can also go on to inflagrate, one such type being the Lithium Ion Battery (LiB). Note 1: It is suggested that LiB type batteries should not be used in IAEA regulated facilities; this should include lithium ion computer batteries, safety illumination and Uninterruptable Power Supplies (UPS) used in small-scale DC control systems. Note 2: Any fire in a nuclear facility is a reportable incident.

Paul Marks asks the rhetorical question, "Can diverse power backups boost nuclear plant safety?" in his review article [1]. His answer is a qualified yes, with the exception of those proposals where a mis-mash of "commercial-grade emergency equipment" spread around a NPP site is suggested; Paul quotes Edwin Lyman with respect to the paucity of the mis-mash approach, "The US industry is proposing to purchase lots of commercial-grade emergency equipment and distribute it in many different places, with the hope that there will be something left no matter what happens"; let us hope that this does not come to pass.

Figure 1. A setup for a battery/EDG power backup system. The batteries can be charged and kept charged either from the grid (usual practice) or from the EDG (during plant testing or emergency grid outages).

Battery Basics, Configuration, Management and Placement

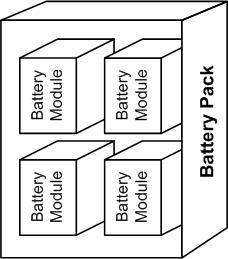

The battery cells will have an indicative voltage (dependant of the relative potentials of the cathodes and anodes) and maximum stored energy (probably measured and stated in kWh). The cells will have charging and discharging patterns and rates and heat rejection demands through charging and discharging. They will be arranged in banks that allow for preferably passive heat rejection (cell cooling). In some instances, the banks will be hydraulically sealed and capable of emersion (especially in tsunami prone areas).

The cells with say an individual potential of 3V will be electrically linked in "battery modules" that have voltages (say from 12V to 48V) or energy delivery (kWh/s) appropriate to requirements. The cells should be fully modular, capable of individual analysis and selectively replaceable, and be arranged in battery packs that allow for preferably passive heat rejection (cell cooling). When interconnected the battery packs may be considered as the NPP "Battery" but may be located both inside and outside of the NPP perimeter. Cell health monitoring systems will be required to provide assurance of capacity and performance during use.

Figure 2. A simplified Battery Pack, defining the terminology [4].

The pack will be designed to be the best compromise between energy storage and the physical demands of the pack including cooling, connectivity and spacing with access for ready module replacement.

The battery will also be designed to suite the cells' structure and electrode and electrolyte compositions, which will control the Specific Energy (Wh/kg), Specific Power (W/kg) and Energy Density (Wh/L), and thus the scale and geometry of the pack; higher SE will provide better use of space and materials.

The power generated and dispatched by NPPs is high voltage AC; batteries are DC plant. The two types of plants require power conversion technologies to operate as part of a generation plant where batteries are used as a backup. Modern technology for converting DC <--> AC is large-scale electronic solid-state; plant that usually has a very reliable performance, See Figures 1 and 3.

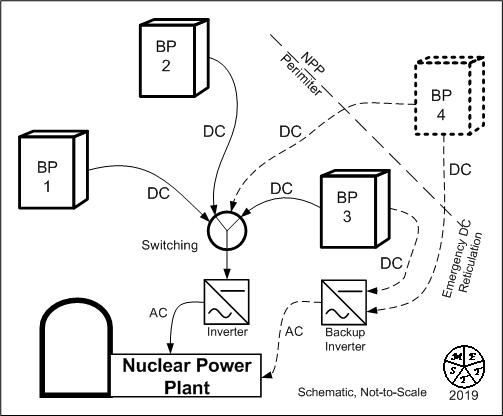

Figure 3. DC reticulation for a battery storage for a NPP.

The NPP Battery in this case consists of 3 to 4 Battery Packs which have individual and flexible monitoring and switching and are NOT situated in close proximity to each other.

The battery interconnections allow for emergency DC/AC reticulation if required.

The operability of the DC system will need to be tested and recorded at regular intervals; batteries, inverters, reticulation cabling, switching and monitoring systems will all need to be checked. The use of a "dummy load" to test the system would be advisable.

The Definition of Perimeter and its Relevance to NPP Backup

In Figure 3 a perimeter fence is indicated that could be considered in two forms, being the physical and inferred (not virtual). The physical would delineate the area that is categorised as NPP, inclusive of, reactor, generation plant, fuel-storage, services, site management, and site logistics, OHS&E and security. This area comes under nuclear safety, treaties (e.g. IAEA), legislation and regulation. If backup emergency power sources are situated outside the physical perimeter then they and their connectivity should be considered as an integral part of the NPP; they are "inferred plant" with respect NPP treaties, legislation and regulation.

Hoffmeister [5] provides an interpretation of Level 4 backup power safety classification being, "LOOP, loss of EDG and loss of SBO: Based on post Fukushima stress test results, many authorities demanded the addition of Level 4 equipment (mobile sets or others). These are sized to support the most important emergency functions depending on the reactor design and are also used as crisis response equipment (e.g. fire engines). They receive the lowest or no nuclear safety classification". Sang-Won Lee et al [6] pictorially suggests that fire-engines and small household/commercial gen-sets be used supplying water to the Reactor Cooling System and Steam Generators in an emergency where cooling water supply is interrupted. Having access to such plant as fire engines, portable gen-sets (e.g. 3kWe) and mobile gen-sets (say 0.5 - 2MWe) is not a meaningful activity either inside or outside the NPP perimeter. The Fukushima disaster showed that access to the reactors and ancillary plant was lost for a significant length of time.

Battery versus Diesel Generator Backup: A Comparison

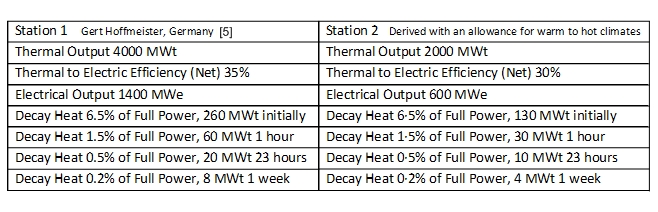

Hoffmeister provides the following guidance on backup power demands before, through and post shutdowns using a 1400MWe (4000 MWt) NPP as an example; using the same factors for a 600 MWe (2000 MWt) thermal constructed in the tropics.

Table 1. Decay Heat from SCRAMED Nuclear Power Plants

It is assumed that the EDGs are 38% efficient and fired with diesel/LFO at a specific energy (SE) of 38 MJ/L, and that only ONE unit is expected to be operating at any specific time, the diesel demand will be around 0.425L/s, 86.4 kL/day, so for a two day full power generation run, the diesel demand would be 172.8 kL. The electricity used (assuming full demand) would be 240 MWh over two days for the diesel. The battery requirement for say the initial 4 hours that will cover of the power failure would thus be 20 MWh or 15% of the S.A. TESLA battery. Following the initial battery supply the diesel(s) could cut in, take up the load from the reactor and begin battery recharge.

Diesels are being produced with a guaranteed start to full load capability of less than or equal to 10s (Wartsila Product Guide [3]); batteries with suitable switching can do the same in nano-seconds, so for an "uninterruptable" power supply, batteries are superior to EDGs; however batteries and EDGs are not mutually exclusive.

Rotating Plant (e.g. Diesel Sets) versus Stationary Batteries - Essential Features: Diesel Plant Challenges

- Fuel Quality: Diesel contamination with sediment and gum produced by microbial (bacterial and fungal) oxidation are a significant challenge in diesel and LFO use. There is need to utilise diesel in certain time limits, less or equal to 20°C ambient temperature 1 year, greater than or equal to 30°C 6 months (British Petroleum Diesel Product Guide). "Old fuel" should be recycled back to suppliers or used in extended testing where the power generated would be reticulated into the grid. Performance testing of EDGs should consider fuel quality and fuel age since refining,

- Start-up Time: Quick-start gas-turbines require a lighter, more volatile fuel to perform well, however lighter more volatile fuels should not be stored or used in plant used in close proximity NPPs. Note: Even a small fire inside the perimeter of a NPP is reportable and will result in a safety audit by the plant's safety auditors,

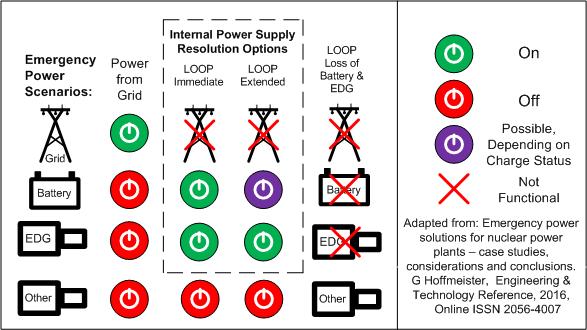

- Power to the plant as a whole or power to specific critical units (reactor core cooling, spent fuel cooling, LOOP, EDG, SPO) is presented schematically in Figure 4 below. In Figure 4 power is supplied from "other sources" could include off-site G/Ts as well as EDGs. The "outside perimeter sets" would likely be stand-by power sources for industry or grid back-up and have a lower standard of maintenance and guaranteed availability than EDGs inside the perimeter.

- Diesel Sets comprise chemical, mechanical and electrical systems that come together to convert chemical energy into electrical energy. They contain moving parts that ware through inadequate lubrication, fail through fuel contamination and components corrosion and have cold-start failures through control system problems. Although they have increasingly become more reliable and efficient, sub-systems in an EDG can fail; US Nuclear standards [6] infer that a failure rate of <1% of start-ups of EDGs is acceptable in a NPP.

- Returning to the Fukushima disaster, the EDGs would have been first challenged by the earthquake; did they handle the vertical and horizontal motion and shockwaves adequately? Forty-seven minutes after the earthquake the site was hit by the tsunami and the EDGs were inundated by the sea. Given that many NPPs are built by the sea and are in known (or potential) earthquake prone areas, Fukushima style disaster scenarios can knock-out EDGs as well as all grid supply.

Rotating Plant (e.g. Diesel Sets) versus Stationary Batteries - Essential Features: Battery Challenges

- Transmission, distribution, reticulation 6.6 kV (regional transmission/distribution), as against say 230 kV primary and 230 kV secondary to grid (i.e. grid link to NPP can be used for battery recharge post an emergency or even during an emergency if other sources of power can cover other emergency needs.

- Batteries have internal resistance that means heating during charging and discharging. The question thus becomes can large stationary sealed battery packs be developed that can expel heat in a passive manner? Can these battery packs survive being inundated, severely shaken and survive tectonic and non-tectonic disasters (e.g. cyclones and tornadoes)?

- Charging and recharging cycles need to be reliable; what are the chances of these cycles failing? Will the solid-state rectifiers and inverters and the switching survive a major tectonic event? Note: They should have a reliability greater than EDGs.

- Cell cases, battery pack construction materials, conduit and connector materials, footings, barriers (security and other), and system competency and resilience are also

Battery Passive Cooling, even at the expense of cooling efficiency with respect to time required for recharge, may become a major factor in battery type selection.

Frequency and depth of testing and maintenance, discharge exercises to ensure that each battery pack (battery component) is fully operational and ready for meeting emergency needs, and protection of valuable safety and security assets are required of NPP batteries. The battery pack shown in Figure 3 suggests there is space between battery modules that could contain air, lightly compressed nitrogen or helium or conductive liquids (e.g. transformer fluids) for heat expulsion. Heat removal would be accomplished by convection inside the battery pack shell and heat convection and low temperature radiance externally.

If the batteries are liable for immersion (as happened in Fukushima) then sealed batteries would be required with adequate heat rejection both in a "dry" and a "immersed" state being provided. Transformer technology may already have the answers for this eventuality.

Battery Back-up is best suited for the early stages of a SCRAM, say in the first two to three hours when the Decay Energy is just coming down from its peak at around 0.1 - 2 seconds after a SCRAM. The EDGs should be operating efficiently soon after the SCRAM and the grid system engineers should be working to see if mains power, being supplementary and/or auxiliary grid power, can be sent to the NPP.

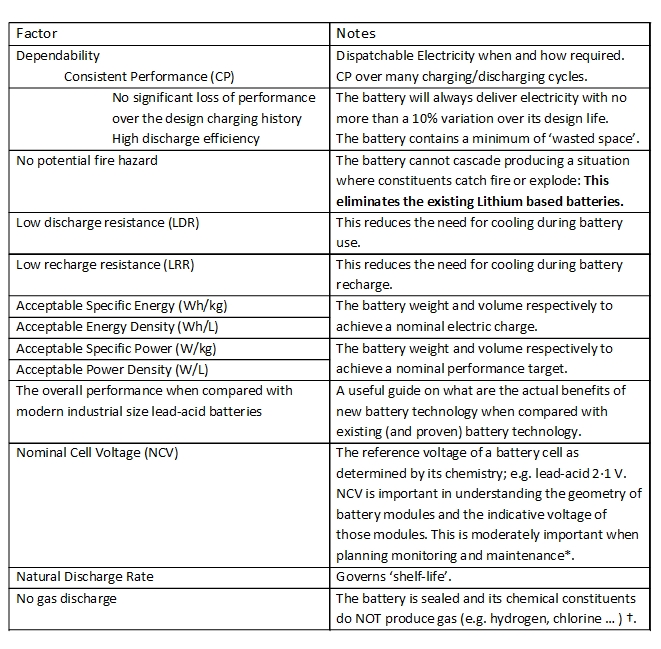

Table 2: What is desired (or not desired) from a Battery Backup for a Nuclear Power Plant

*High NCV has another advantage. In a reaching module voltage of say 12V either a six or eight cell series connected format could be used. The six cell (2V) format would have some space advantage over an eight cell (1.5 V) format in terms of space and mass, and a maintenance (and cost) advantage in that fewer cell monitoring connections would be required. NCV will probably not be critical in the selection of battery systems for NPP backup. †Note: Lead-acid batteries can produce hydrogen during charging.

Batteries with high Specific Energy/Specific Power are extremely important for powering vehicles and running hand-held electronic devices; having high electrical energy but only demanding small space and having low weight is important in batteries that are being designed for electric vehicles (EVs). Stationary batteries used in industrial situations, including NPPs, only have restrictions on space and mass with respect to their designers' specifications, site restrictions and relative installed total cost.

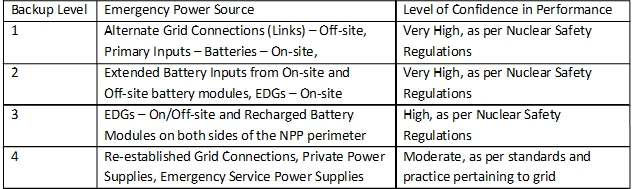

Table 3. Emergency Power Sources and Confidence Rating

Developments in large stationary industrial batteries have the likely prospect of providing the nuclear power industry with a new primary means of powering NPP shutdowns in a more thorough and secure way than was demonstrated by EDGs in the Fukushima disaster.

Battery recharge from EDGs should be a feature of new and refurbished NPP backup systems; the recharge (followed by discharge) would be a monitoring and maintenance procedure. Battery recharge from EDGs with surplus capacity during emergencies should be a built-in option than will assist in following the demand and supply pattern and providing power for unexpected secondary disruptions.

Depending on how total back-up is configured having part of the back-up outside the NPP perimeter is a hazard reduction proposal. Having sufficient capacity inside the perimeter to manage Decay Heat following a SCRAM is also a hazard reduction measure; if that capacity was in the form of battery back-up that could be available in nano-seconds and last for several hours, all the better.

The brave emergency responders in both Chernobyl and Fukushima Nuclear Disasters were not matched with the seriousness of the situations. Such professionals and their appliances being, fire-engines, water-tankers, emergency generators and personal protective equipment etc are not suited for a situation where the depth of the disaster cannot be fully and quickly understood by nuclear reactor engineers, technologists and scientists much less non-nuclear responders. Working inside the perimeter of a NPP both during normal operation and emergency situations is for specially trained professionals. Other emergency professionals are best utilised in population evacuation and relocation activities.

Recommendations

a. The demotion of the Primary EDG sets from Backup Level 1 to Backup Level 2 is a goal that should be sought if new battery technologies can provide additional back-up power security for NPPs.

b. Diesel Gen sets versus G/Ts. Some G/Ts have been approved however the start-up times tend to be longer. G/Ts can run on almost any liquid fuel, however fast start-up is best achieved with volatile fuels (e.g. Avgas, natural gas supplemented with diesel, condensate), this should not be a feature inside the NPP perimeter. G/Ts could best operate as external backup plants sited outside a NPP perimeter, but be subject to nuclear plant regulations and audits.

c. Since on the hazard spectrum nuclear accidents rate very low on frequency and very high on consequence, additional safety features and staff management and training should be undertaken with respect to SCRAM management and the planning for their safe resolution.

d. Major Battery Backup should provide extra time for putting NPP emergency plans into operation thus avoiding or mitigating damage to NPPs.

Sources

1. "Can diverse power backups boost nuclear plant safety?" Paul Marks, New Scientist, 8 March 2012.

2. Bataan NNP (Philippines), Personal Inspections and Westinghouse/NAPOCOR documentation.

3. "Wartsila to supply emergency diesel generators for Finnish nuclear power plant", press release, May 2013.

4. MIT Electric Vehicle Team, 2008.

http://web.mit.edu/evt/summary_battery_specifications.pdf

5. Emergency Power Solutions in Nuclear Power Plants - PDF: Gert Hoffmeister, IET Publishing, Reference, article, March 2017.

6. "Extended Station Blackout Coping Capabilities of APR1400", Sang-Won Lee, Tae Hyub Hong, Mi-Ro Seo, in: Young-Seung Lee and Hyeong-Taek Kim, Science and Technology of Nuclear Installations, Volume 2014. Article ID 980418, 10 pages.

http://dx.doi.org/10.1155/2014/980418

7. Emergency Diesel Generators, Section 11, 2009.

https://www.nrc.gov/docs/ML1122/ML11229A161.pdf

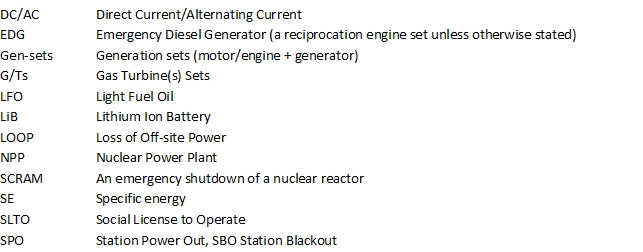

Glossary of Terms

Author

Dr Mike Clarke, Consulting Engineer, Infrastructure Development & Resource Management, of M.E.T.T.S. Pty Ltd, Gold Coast, Queensland.

NOTE:

You are welcome to quote up to a maximum of three paragraphs from the above white paper, on condition that you include attribution to this website, as follows:

SOURCE: M.E.T.T.S. Pty. Ltd. Website http://www.metts.com.au

M.E.T.T.S. Pty. Ltd. - Consulting Engineers PO Box 843, Helensvale QLD 4212, Australia TEL: (07) 5502 8093 • (Int'l) +61-7-5502 8093 EMAIL: metts[at]metts.com.au Copyright • Privacy • Terms of Use © 1999-2020 M.E.T.T.S. Pty. Ltd. All Rights Reserved. |

.