M.E.T.T.S. - Consulting Engineers > White Papers > Clean Coal Technology and Enhanced Oil Recovery - Matches and Mismatches

Clean Coal Technology and Enhanced Oil Recovery - Matches and Mismatches

Dr. Michael C. Clarke, CPEng, FIEAust, FAusIMM, RPEQ

CEO, M.E.T.T.S. Pty. Ltd.

Consulting Engineers, Resource Management and Infrastructure Development

Gold Coast, QLD, Australia

Email: metts[at]metts.com.au

Share this page:

ABSTRACT

Clean Coal Technology (CCT) has multiple meanings to various audiences. To the traditional coal utilisation industries, such as the power industry, CCT means the reduction of emissions of nitrogen oxides, sulphur oxides and particulates, coupled with improvements in the efficiency of converting coal into electricity [1]. To those who are committed to the hypothesis of anthropogenically caused climate change being caused by increases in atmospheric carbon dioxide, the CCT must include the permanent removal of coal sourced carbon from the atmosphere. To the more extreme environmentalists, Clean Coal Technology is an oxymoron, and that all coal technologies should be relegated to the past in favour of a solar powered world.

Where the scientific and the general communities are committed to find ways of permanently capturing carbon dioxide produced in power generation, geo-sequestration -- the entombing of carbon dioxide in the earth -- is looked upon as the most feasible technical solution. The proposals for geo-sequestration include burying carbon dioxide in, deep and un-mineable coal seams (as is being trialled in Queensland, Australia [2]), in depleted natural gas fields and lastly in depleting oil fields.

Forcing carbon dioxide into depleting oilfields has the potential to lock-away very large amounts of carbon dioxide but more importantly ‘squeeze’ significant remnant oil out of the oilfields. There are synergies between power generation (using coal or lignite), geo-sequestration of carbon dioxide and Enhanced Oil Recovery (EOR). The selection of the specific EOR technology that is best suited for the oilfield will depend very much on the oil’s viscosity, API (specific gravity) and the physical geological structure of the oil reservoir [3].

Introduction

Where carbon sequestration is being considered as an essential aspect of CCT, considerable interest is been created regarding the likely synergies of carbon dioxide (CO2) capture post power generation, geo-sequestration in depleted oilfields and thence the use of that carbon dioxide in Enhanced Oil Recovery (EOR) from those oilfields. Victorian lignite fired power generators with their close proximity to the depleting oilfields of Bass Strait, Australia have been viewed as suitable destinations for carbon dioxide produced from lignite based power generation [4]. Similar proposals for natural gas based power generation are being developed by Norway for CO2 geo-sequestration under the North Sea. Likewise the UK and Denmark will be the sources of carbon dioxide derived from both imported coal and natural gas for injection into the rapidly depleting North Sea oilfields.

The injection of CO2 into a depleted oil reservoir can mobilise otherwise stranded oil which can account for greater than 20% of the volume recovered in primary extraction [5]. By combining CO2 injection with steam injection, another method of enhancing oil recovery can be gained. This tertiary oil recovery can be achieved with the geo-sequestration of considerable unwanted CO2 in stable and secure geological formations that by their very nature and depth are traps for gases and liquids (the carbon dioxide being normally injected and maintained by pressure as a super critical liquid). In this paper, coal and lignite fired power generation are being considered in terms of their EOR synergies.

Matches and Mismatches of Technology

The synergies of each specific process, they being coal based power generation, CO2 capture, CO2 geo-sequestration and thence EOR, will need to be considered for each project development, with some of the critical factors being the nature and size of the CO2 production, the purity of the CO2, the size and structure of the oilfield, and the physical and chemical nature of the oil.

The first significant aspect of the technology synergies is the type of power generation (coal or lignite conversion to electricity). The traditional power generation looks at burning fuel using air as an oxidant. The resulting flue gases are primarily a mixture of carbon dioxide, nitrogen and water vapour. The carbon dioxide and water vapour are the products of combustion, whilst the nitrogen is largely inert in the conversion reaction, and simply significantly increases the volume of gas that must be managed. The separation of carbon dioxide from a gas mixture that is 80 - 90% nitrogen is possible using chemical or physical means, but is expensive and adds additional process complexity, size of plant and risk to the power generation process.

Firing coal and lignite with oxygen (as against) air makes good technical sense and increasingly good economic sense. Traditional cryogenic separation is well understood, and advances in solid membrane separation are promising oxygen at significantly lower CAPEX and OPEX [6]. Matching oxy-firing with EOR is a good match; matching air-firing with EOR is a poorer match.

EOR Carbon Dioxide Based Technologies

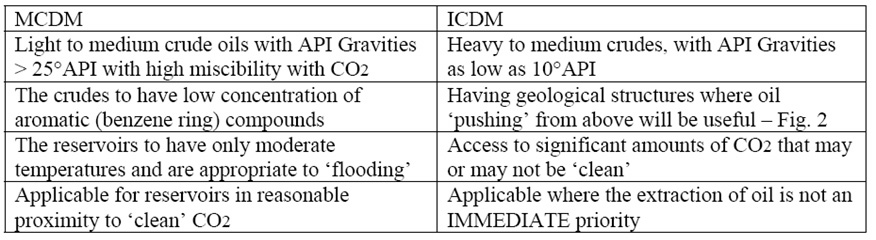

Two EOR processes have been developed that use CO2 as a tool for mobilising crude oil in reservoirs. These processes use the miscibility (or lack of miscibility) of oil and CO2 as the governing physical/ chemical property. The processes are the Miscible CO2 Displacement Method (MCDM), Figure 1 and the Immiscible CO2 Displacement Method (ICDM), Figure 2. Table 1 summarises the desirable crude and reservoir properties that apply to MCDM and ICDM technologies.

Table 1. The relative properties of the MCDM and ICDM EOR processes [3].

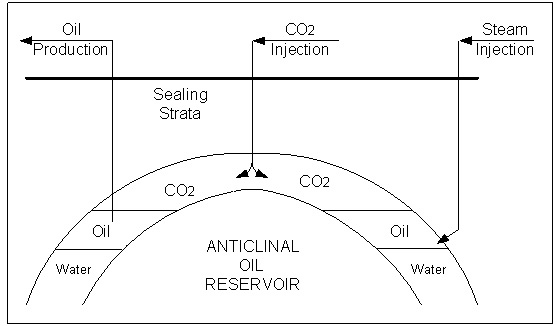

The MCDM process requires the dissolution of the CO2 in the oil to form a single phase fluid with low viscosity, good fluidity and low physical affinity to the host rock. For the MCDM process the CO2 should be essentially free of sulphur and other contaminants from the combustion process. The IDCM process is essentially a physical process with the creation of a high pressure gas (CO2) cap above a depleted oil reservoir being the aim – Figure 2. There will be some dissolution of CO2 in the oil, and this will indeed help to lower the viscosity of the oil, but the take up of the CO2 in the oil will be limited and will be relatively slow. The ICDM process itself will also be far slower than the MDCM and would need to be looked upon as a long-term investment.

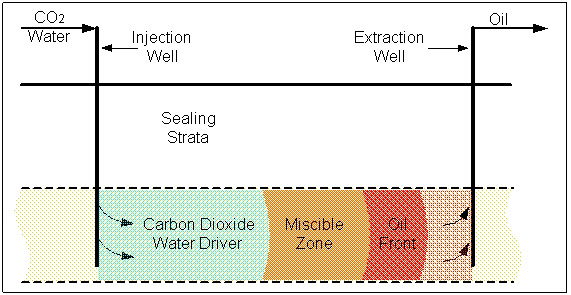

Figure 1. Miscible EOR

Figure 2. Immiscible EOR

Figure 1 shows the concept of CO2/water flooding. This system uses the alternating injection of water and carbon dioxide to flood the oil reservoir. In homogenous reservoirs the technology can be very effective. The challenge with this type of EOR is to avoid channelling (fingering) and gravity override resulting in early breakthroughs causing major losses in oil recovery. The US Department of Energy is researching ways of using foams to overcome these challenges [7].

In terms of CO2 sourcing from existing coal fired power generation, the need to concentrate the CO2 (as well clean the CO2 for MCDM) is necessary to ensure the successful dissolution of the CO2 in the crude. In post-combustion CO2 capture systems that utilise amine based CO2 capture to separate unwanted nitrogen from CO2, the necessity of ensuring that flue gases are clean so as not to foul the amine should provide the required quality of CO2 for ready dissolution in the crude oil. (Such a scheme is being practiced at the Weyburn oilfield in Saskatchewan, Canada.) There is a cost however, with this cost being the CAPEX and OPEX (including amine make-up and power/heat consumption) of the CO2 amine capture/separation system [8].

In the new power generation systems, such as Integrated Gasification Combined Cycle (IGCC) that will use oxygen in place of air for firing coal, the process does include the cleaning of the waste process gas. This gas will contain mostly CO2, but also some residual nitrogen, nitrogen oxides, sulphur compounds, volatile organic compounds, plus particulates. The need to clean the waste gas stream to facilitate MCDM would add another major layer of technology on the power generation complex, and another layer of significant operating costs but would not be a factor with IDCM.

Geo-sequestration and MCDM

MCDM is generally a rapid process, in that CO2 is pumped into a an oil reservoir, dissolves in the oil and forms a single phase fluid, and thence that fluid is pumped towards a production well. The oil and the CO2 are separated, with most of the recovered CO2 being reinjected, with in some instances around 70% of the CO2 being cycled through the reservoir. Given that there is a very significant requirement to recycle CO2 and that there are losses on separation, the ability of MCDM to be a significant and verifiable geo-sequestration process is limited.

ICDM has a much higher potential to be a very significant long-term capture system for CO2. ICDM is essentially the creation of a high pressure gas (CO2) cap above a depleted oil reservoir – Figure 2. There will be some dissolution of CO2 in the oil (resulting in oil swelling), and this will indeed help to lower the viscosity of the oil, but the take up of the CO2 in the oil will be limited. (Note: Although only limited examples of ICDM exist, there is a successful operation in Bati Raman, Turkey where the ICDM EOR is used in the recovery of a very heavy crude [9].)

CCT Power Generation and Enhanced Oil Recovery

In areas where there is close proximity of power generation facilities producing a concentrated but impure CO2 waste stream and oil reservoirs where ICDM is applicable, a hybrid EOR scheme could be utilised. By diverting some steam from power generation during non-peak periods, thermal EOR could be used to enhance ICDM in the recovery of heavier crudes. The mix and timing of this hybrid scheme would need to be developed with a good understanding of the reservoir and the nature of the crude, with income raised from CO2 sequestration being the initial cash-flow before enhanced oil recovery cuts in as the major revenue source.

For MCDM EOR CO2 produced during power generation looks less attractive due to its impurities. If amine recovery of CO2 is employed in an air-fired power generation system, the flue gases will need to be pre-cleaned before nitrogen/ CO2 separation, thus producing a clean carbon dioxide stream, but at some considerable cost. Balancing the cost of amine based CO2 separation with returns from carbon capture and EOR will be favourable in some situations. The cost of flue gas clean up of oxy-fired coal and lignite power generation will also be accommodated in some EOR projects. The economic success (or not) of each project will be very site specific.

Opportunities for Power Generation related EOR

There are opportunities for significant EOR in Asia, with one particular example being the heavy crude oilfields of Sumatra, Indonesia. The CO2 could be produced from new local coal/lignite fired power generation facilities and/or oil refining with co-generation. In many parts of Asia there are medium sized examples of oilfields that have seen their production significantly drop over the last fifty years. In planning new power generating facilities these oilfields should be considered as part of the total energy development of the region, and EOR prospects using MCDM, ICDM or hybrid should seriously be examined.

Conclusion

The application of ICDM EOR technology in appropriate oilfields has the potential of being a very significant and verifiable geo-sequestration system. It would, over time, increase the recovery of otherwise stranded crude oil and earn credits as a secure and permanent geo-sequestration destination for CO2 produced in electricity generation based on Clean Coal Technology.

The success of EOR projects that reply on CO2 produced through coal and lignite utilisation in power generation will be very site specific. Those projects that have the ‘right’ technical and economic ingredients will be very profitable.

References

1. Clean Coal Technology: How clean is it and how clean can it be? M. C. Clarke and P. Bennett (ACIRL), IEAust Seminar, Brisbane Australia, October 8, 2007.

2. The Callide Oxy-fuel (Demonstration) Project. Queensland Department of Minerals and Energy, Queensland Government announcement, April 2008.

3. Enhanced Oil Recovery using Carbon Dioxide in the European Energy System. E. Tzimas et al. Institute of Energy, Petten Netherlands, Dec 2005 (web published).

4. Victorian Power and Liquids, Project Summary. August 2003. Company Presentation.

5. US Department of Energy (USDoE) Brochure on Enhanced Oil Recovery, March 2006.

6. Ion Transport Membrane (ITM) Oxygen Separation, Air Products Inc (USDoE funded) project presentation, October 2007.

7. DOE R&D puts CO2 EOR on verge of explosive growth. US DoE, Office of Fossil Energy and National Energy Technology Laboratory, April 2006 (web published).

8. Techno-Economic Study of CO2 from an Existing Coal Fired Plant: MEA Scrubbing versus CO2/O2 Recycle Combustion. D. J. Singh et al. Energy Conversion and Management Journal, Vol 44/19, Nov. 2003.

9. Enhanced Oil Recovery Scoping Study. Electric Power Research Institute USA (EPRI), October 1999.

NOTE:

You are welcome to quote up to a maximum of three paragraphs from the above white paper, on condition that you include attribution to this website, as follows:

SOURCE: M.E.T.T.S. Pty. Ltd. Website http://www.metts.com.au

Share this page:

Author: Michael C Clarke

(Michael C Clarke on Google+)

M.E.T.T.S. Pty. Ltd. - Consulting Engineers PO Box 843, Helensvale QLD 4212, Australia TEL: (07) 5502 8093 • (Int'l) +61-7-5502 8093 EMAIL: metts[at]metts.com.au Copyright • Privacy • Terms of Use © 1999-2014 M.E.T.T.S. Pty. Ltd. All Rights Reserved. |

.